Are you looking for perfection and precision? Look out for the new milling robot arm. It is an industrially advanced robot arm that is fully independent and autonomous to perform the milling tasks.

The milling robot arm works on coded set instructions to perform exact cuts on moulded joints as per the industrial requirements. The movements are necessary to produce the highest quality end parts. They have automated strategic robot milling tools systems that are adjustable and uniquely designed to cater to specified removals.

At all lengths, any object with any dimension can be moulded and milled by the milling robot arm. The milling robot arm working by adjusting the robotic programs and end-of-arm tools stored on the brain of the robot.

Design

The milling robot arm is amazingly designed by having milling work cells that act as the changing “nerve” of the milling robot arm. The milling work cells work to allow multiple part fixtures and functionalities that help increase security and increase the milling production rates.

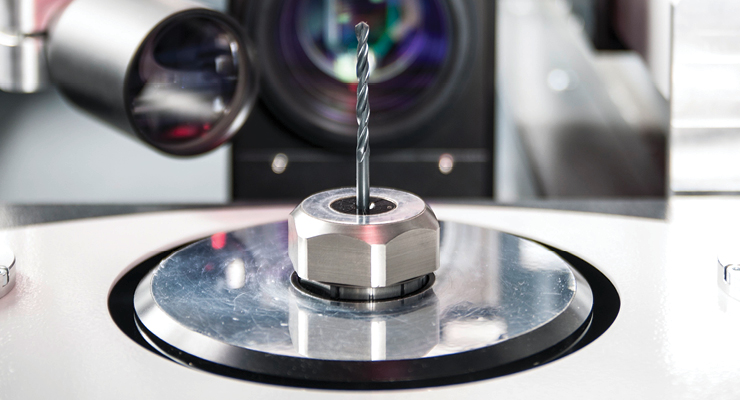

Given the fact that the milling robot arm is movable, it is designed by having jointed gears attached on the ends of each little arm. The little arms allow for multiple tasks to be carried out concurrently. The milling robot arm undergoes an extremely critical refurbishing phase which allows for milling advances to be made.

It is designed on four rails that allow the whole system mobility. The mobility feature creates motion enabling the robotic arm to operate in not only one single place of the whole building set-up. It allows for the milling robot arm to move from the task end-points to begin other milling tasks.

It has some of the most sophisticated assembling finished on its designs to help limit the occurrence of unnecessary system failures. The milling robot arm does have the speed enhancer tool. The tools allow for the effectiveness of the milling arm robot to be calculated and evaluated during robot set-up. The enhancers also allow for the milling robot arm to be assembled and dismantled easily and appropriately.

Milling Robot Arm versus the CNC (Computer Numeric Control)

The Computer Numeric Control (CNC) milling methods comprised of early milling techniques that were employed by most industrial milling companies. They involved cumbersome computer operations involving the use of machines to perform the milling procedures and tasks.

The advent of the milling robot arm has seen the radical shift of the milling tasks from simple, genera; tasks to a much more sophisticated and easy done process. The milling robot arm has brought about the revolution factor. This is simply because the milling robot arm can independently run multiple operations at a single point in time.

The milling robot arm operates to ensure that precision is met by allowing stringent operating procedures. The milling robot arm is smaller in size compared to the conventional CNC. This allows investors to set up and perform the milling procedures in a relatively smaller workspace.

Gone are the days of setting up huge complicated CNC machines that consumed a lot of space with little output generated. The cost factor has immensely been affected by the onset of the milling robot arm machine. Given the fact that the milling robot arm can do multitask allows multiple numerous operations to be carried out at a single point in time.

This reduces the deployment of multivariant machines to perform tasks differently. In essence, it helps investors reduce the cost of deploying multiple machines to undertake the milling functions.

Conclusion

Having the milling robot arm in any milling company creates an amazing ripple effect in production terms. It upgrades the milling process from just the general routine to a whole new magical experience.

Thinking about the right milling solutions for your milling tasks? Think of integrating the milling robot arm into your systems. It is an investment worth appreciating.