There are numerous straightforward ways those utilizing 3D printing or additive production can get far better prototypes or production parts quicker.

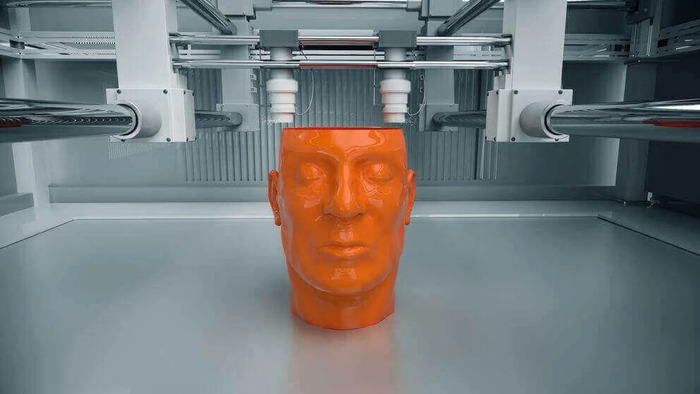

Many businesses utilize 3D printing, a sort of additive production, for turning or prototyping outside generation components. It’s a computer-based procedure which lays down layer after layer of a product until it’s complete. The procedure employs plastics or metal and begins with a 3D digital version of the last object.

Here are tips that can help users enhance print quality, together with a couple extras for raising 3D printing rate.

Must check- High strength 3D printing service

- Adjust the mattress and place the nozzle elevation.

The simplest way to increase 3D print quality is to guarantee the mattress is leveled and nozzle space is suitably set. Most printers have a recommended space between nozzle and bed.

A feeler gauge or a very simple piece of paper might help in placing this space. When the nozzle is correctly set up, the paper or judge must slide beneath the nozzle. No force is necessary to have it to go beneath the nozzle. This procedure ought to be repeated three or more times to guarantee that it’s functioning nicely.

- Examine the nozzle temperature.

The nozzle thickness, and there might be many nozzles, impacts print quality. When it’s too hot, there’ll be filament strings involving parts that are spaced. On tall bits, high temperatures typically melt down the top layers and deform the last object.

If you’re printing a taller item, put in a one-centimeter block on the other side of the printer construct plate that’s on the other side to eliminate the hot nozzle in the part. This will allow the nozzle to be trendy. If sequences of filament appear involving constructions, look at using a shield wall or structure. These are normally found in slicer applications.

- Use different construction plates to make unique outcomes.

Different construct plates produce unique textures on the item. Bed materials like PEI, glass or Kapton tape typically leave a smooth coating. Painter’s tape or polycarbonate sheets render a matte finish.

If you’re going to use glue or spray the surface, then use only enough to pay the plate. Using an excessive amount of paint or glue deforms the thing and creates scratches. These make it difficult to remove the item in the plate, and pushing it off may harm the item and divide the plate.

- Pay careful attention to your printer modification and maintenance.

Each 3D printer includes techniques and features which enhance print quality. And printers must be preserved to find the best printing.

By way of instance, the printer railings should be cleaned and lubricated. Along with the gantry ought to be at precisely the exact same elevation on either side in case your printer uses stepper motors. Additionally, check to determine whether there are some weak spots in the framework. Tighten all bolts and make certain the firmware upgraded in accordance with the manufacturer’s guidelines.

- Manage the filament carefully

Many filaments are hydrophilic and absorb water from the atmosphere, which causes printing issues. Damp filaments extend during extrusion since water becomes warm and flows in the plastic.

The filament frequently crackles or pops because the vapor escapes. There might also be smoking.

You may wash the filament on the spool at the oven for a couple hours in low temperatures. Some people today construct a heated bin which holds the filament before it is fed to the printer.

- Utilize a slicer

Slicers convert 3D models into education sets which run the printer. All are free.

If a print is not as great as it needs to be, fix the slicer’s hyper or good excellent setting. When it may impede the printing process, print quality will improve.

That having been said, don’t correct the slicer following a couple of prints. Assess the issue and alter slicer settings slowly. As you alter the settings, continue printing to see whether there are changes. Slicers have many configurations. Spend a while to find them; you’ll get far better support from the slicer.

- Reduce the printing rate

Echoes or ringing round the edges of attributes on the last thing decrease the visual quality of your final item. These deflecting lines are often brought on by vibrations in the extruder’s functioning. To repair this issue, reduce the printing rate. Verify the extruder has the space to maneuver so the printed place doesn’t overheat or make additional quality issues.

- Do not neglect to post-process.

After the item is published, it takes a while to get rid of any flaws. By way of instance, do away with little imperfections with adhesive or a tiny sharp knife, particularly if painting or painting is intended.

Some compounds, like ABS, are harmonious with acetone vapor remedies that leave a shiny finish. Nonetheless, these remedies weaken the design. And mix or copper-infused plastics could be made better with some sanding and distinctive therapy.