After several debates about whether robots will replace CNC machines, the two technologies merged to form CNC robotics. Given the initial distinct nature of CNC machining and robotics, many potential users still question whether the merge is necessary.

Fixing a robot in front of a CNC machine is necessary for loading and unloading to CNC machine needs. Besides other benefits, the process becomes cost-effective, as explained in this article.

First, you should find out the kernel of CNC operations. Next, you will learn unique things about modern robots that make them the best partners for CNC machines.

Lastly, the article selects relevant parts of CNC and robotics and combines them to make an informed investment decision. Let’s get started.

What You Can Do with CNC Machines

Computer Numerical Control is the use of coded instructions to guide the tools machining automatically. The computer’s control code is called G-code.

You (or the machine’s manufacturer) feed instructions in the computer to dictate how the machine’s moving parts undertake specified actions. The device removes portions of metals, wood, plastic, glass, composite, or foam.

The most notable CNC machining applications are additive processes such as 3D printing and liquid injection molding.

Examples of tasks you can accomplish with CNC machines are:

- Milling

- Drilling

- Turning

- Broaching

Here is what you should know about the role of CNC in each of the above machining tasks.

Milling

This involves removing materials from the workpiece through rotating multipoint cutting tools. It subdivides into:

- Peripheral milling.

Sometimes you want to shape the outer surfaces of a metal, wood, or plastic. Cutting the unwanted portions of a material using a CNC machine is called edging.

Alternatively, you can form grooves or remove the ends of the material—peripheral milling.

Drilling

CNC drilling entails making holes in a material through mass production. Some machines possess many spindles to enable them to make several holes, of varying diameters, in a workpiece.

Turning

CNC turning is a single-point removal of materials in a rotating workpiece. Here, a lathe machine feeds the cutting tool linearly along the workpiece’s surface.

Broaching

It entails creating keyways by cutting motions along the Z-axis. It is a unique machining process because it relies on a broach—a unique cutting tool.

What Is the Main Difference between a CNC Machine and a Robot?

The striking difference between a CNC machine and a robot is that a CNC machine is programmed using the G-code. A manufacturer programs a robot using their specific (programming) language.

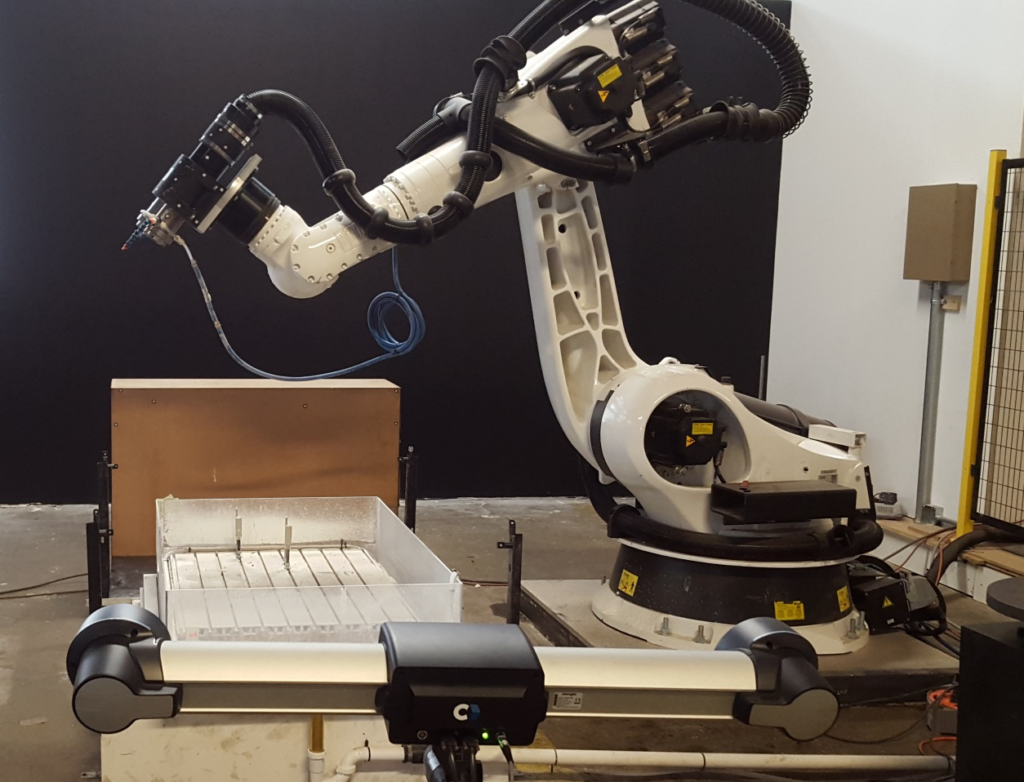

Combining the functionalities of CNC machines and robotics gives birth to cnc robotics.

The Role Robots in Mass Production Such as CNC Machining

Robots participate in mass production, such as machining.

CNC machining entails milling, drilling, and lathing. The process involves loading the machines with raw materials such as metals, glass, plastic, or wood.

The CNC machine works on the workpiece to produce the desired shape. Finally, you need to remove the operated workpiece from the machine. This is called CNC unloading.

You use robots in large part machining because the environment is unsafe for human labor. For example, the process generates fatal temperatures. Most of the time, the workpiece is too heavy to carry with human energy.

Most importantly, using robots in CNC robotics is necessary to cut operating costs. You can reduce operating expenses because you do not pay huge wages and salaries to keep the process running.

Additionally, robots do not undergo regular maintenance, helping to minimize manufacturing costs. The result of reduced costs and uplifted runtime is what makes an ocean of firms realize their ROI quickly.

Other robot activities related to machining are pick and place, welding, and sorting of the CNC products.

Conclusion

Do you want to boost industrial mass production performance? Rethink CNC robotics.

It is the key to faster, convenient, and economic-friendly large part machining. It propels your ROI by squeezing expenses and increasing productivity.